◆ Carbide tipped cutting edge welded to the tough alloy steel body

◆ Special Multi-Cut design(3-ply)help to remove chips and reduce cutting resistance

◆ High cutting speed, High wear resistance and considerably longer tool life

◆ Can achieve good drilling performance on complicated(harder)materials

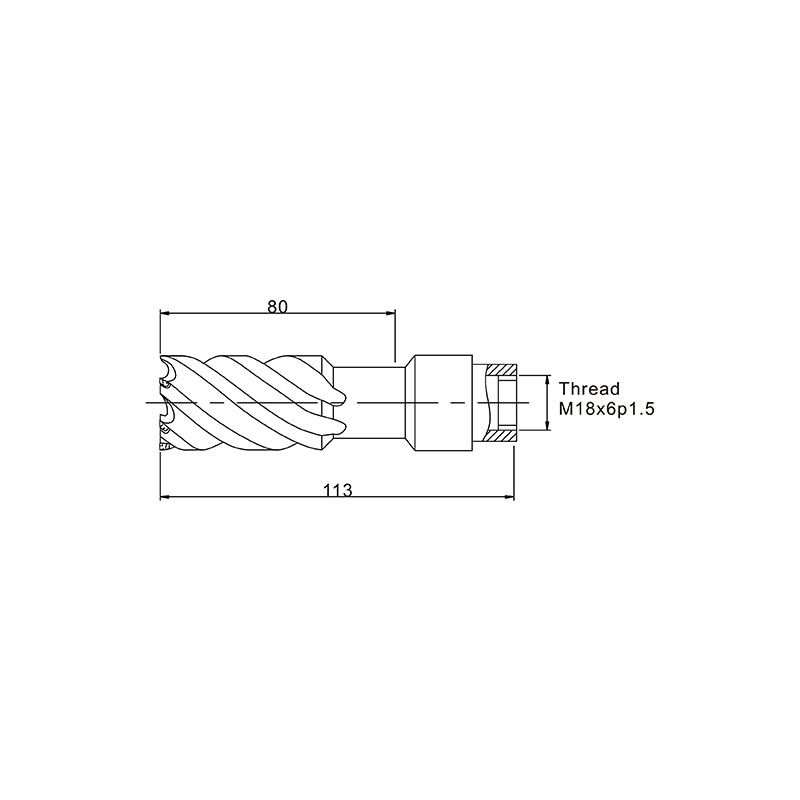

◆ M18×6 p1.5mm Thread Shank

◆ Specially for FEIN and HITACHI magnetic drills

◆ Used on the Magnet-Seat Drilling Machines and Press, Milling machine also available

◆ Best chioce for annular drilling on steel plate materials and large workpieces

◆ Special multi-Cut design help to remove chips and reduce cutting resistance

◆ With center pin for piloting and ejecting the cutted piece

◆ Much higher in cutting efficient and better cutting result than the traditional Twist Drills

◆ Suitable for Steel Structure Projects, Railway-Traffic, Bridging, Shipbuilding, Aviation and Spaceflight Industry